Custom projects present you with an entirely new scope of parameters that must be considered. While each project will require its own combination of “Art and Science”, listed below are some general categories of thought you may wish to review. Each step of the decision tree will lead you the next decision. At Arte Hardware, we try to work with you upfront in determining the direction of your project and share options you may not have considered.

Custom projects present you with an entirely new scope of parameters that must be considered. While each project will require its own combination of “Art and Science”, listed below are some general categories of thought you may wish to review. Each step of the decision tree will lead you the next decision. At Arte Hardware, we try to work with you upfront in determining the direction of your project and share options you may not have considered.

The thought process below holds true for a Custom Residential, Commercial or Hospitality application.

Schedule

Custom projects simply require more time. There is the design phase where you dial in the visual and application you desire to complete your space. There is then a mechanical phase where we make sure that what you have designed can work for the technical application, such as: Is it trim for another manufacturers latch set or is it a simple pull for a statement entry? Then there is a tooling phase, where the actual tools or molds (which vary by material and conversion technology you employ) are created, tested and a sample created. An approved sample then moves to production, assembly, shipping and finally site delivery. While there is no one set timeline, as a general rule from when your initial drawings and concept are completed, your custom project will more than likely require 90 – 180 days: 120 days as a good general rule. The number of components and volume of items will then come into play in the final timing. You will receive realistic estimates once we understand the scope of your project. When it comes to our mutual sanity – more time is better than less. Some processes, just like the creative process, cannot be rushed.

Custom projects simply require more time. There is the design phase where you dial in the visual and application you desire to complete your space. There is then a mechanical phase where we make sure that what you have designed can work for the technical application, such as: Is it trim for another manufacturers latch set or is it a simple pull for a statement entry? Then there is a tooling phase, where the actual tools or molds (which vary by material and conversion technology you employ) are created, tested and a sample created. An approved sample then moves to production, assembly, shipping and finally site delivery. While there is no one set timeline, as a general rule from when your initial drawings and concept are completed, your custom project will more than likely require 90 – 180 days: 120 days as a good general rule. The number of components and volume of items will then come into play in the final timing. You will receive realistic estimates once we understand the scope of your project. When it comes to our mutual sanity – more time is better than less. Some processes, just like the creative process, cannot be rushed.

Materials

We can provide you access to a number of materials for your custom decorative hardware. Sometimes your visual will drive the material requirement, sometimes your schedule and sometimes your budget. We craft hardware from a number of materials- predominantly artisan bronze, brass and stainless steel. We also have access to glass and crystal for projects requiring such. Each of these materials come with their own tooling requirement, tooling cost, material cost and timeline. While your visual will be the #1 driver as to material selection, we will walk you through any additional options you may have for schedule, cost or visual requirements.

We can provide you access to a number of materials for your custom decorative hardware. Sometimes your visual will drive the material requirement, sometimes your schedule and sometimes your budget. We craft hardware from a number of materials- predominantly artisan bronze, brass and stainless steel. We also have access to glass and crystal for projects requiring such. Each of these materials come with their own tooling requirement, tooling cost, material cost and timeline. While your visual will be the #1 driver as to material selection, we will walk you through any additional options you may have for schedule, cost or visual requirements.

Budget

While we are firm believers that “custom” does not mean a “blank check”, custom is typically costlier than off the shelf product. However, that will depend upon who’s product you compare it to and you will find in many cases your custom project with Arte Hardware may be in line with others “off the shelf” product. Your project is unique unto itself, requires its own custom tooling, its own custom small run and unique materials and finishes. These demands are simply a byproduct of creating any piece of art and making a lasting statement on your project. We will quickly provide an estimate for your custom project based on visual, material, quantity and timeline. We will outline any additional costs that could occur so that you have a full picture of the scope and potential costs. Custom Decorative Hardware is our only business, not a side operation. This allows our factories, partners and small run processes the ability to pass along our efficiencies to your project and budget.

While we are firm believers that “custom” does not mean a “blank check”, custom is typically costlier than off the shelf product. However, that will depend upon who’s product you compare it to and you will find in many cases your custom project with Arte Hardware may be in line with others “off the shelf” product. Your project is unique unto itself, requires its own custom tooling, its own custom small run and unique materials and finishes. These demands are simply a byproduct of creating any piece of art and making a lasting statement on your project. We will quickly provide an estimate for your custom project based on visual, material, quantity and timeline. We will outline any additional costs that could occur so that you have a full picture of the scope and potential costs. Custom Decorative Hardware is our only business, not a side operation. This allows our factories, partners and small run processes the ability to pass along our efficiencies to your project and budget.

Finish

There are two types of finishing you will want to consider – “Plated” or “Oxidized” finishes with a protective clear lacquer coat or a “Living” finish which can come with a wax coating, polish or no protective coating at all. Living finishes are quite popular in non-finished brass and various bronze visuals. A “Living” finish is “alive” and will bring out the natural beauty of the metal as it oxidizes with the impact of sun, air, moisture, hand oil, etc. While a very popular artisan look, you may want to consider what all the other architectural hardware surrounding your custom work will look like. If the hinges, cylinders, door stops, closers are in a non-living finish provided by a stock manufacturer, you may want your visual aging process arrested to evolve slowly in unison versus letting nature take its course. As with every step of this process, we will make sure these considerations are covered. For all custom projects, we require a finish sample target from you.

There are two types of finishing you will want to consider – “Plated” or “Oxidized” finishes with a protective clear lacquer coat or a “Living” finish which can come with a wax coating, polish or no protective coating at all. Living finishes are quite popular in non-finished brass and various bronze visuals. A “Living” finish is “alive” and will bring out the natural beauty of the metal as it oxidizes with the impact of sun, air, moisture, hand oil, etc. While a very popular artisan look, you may want to consider what all the other architectural hardware surrounding your custom work will look like. If the hinges, cylinders, door stops, closers are in a non-living finish provided by a stock manufacturer, you may want your visual aging process arrested to evolve slowly in unison versus letting nature take its course. As with every step of this process, we will make sure these considerations are covered. For all custom projects, we require a finish sample target from you.

Functions

Be prepared to share the various functions or trim applications you require:

Be prepared to share the various functions or trim applications you require:

- Push Pull sets

- Back to Back pulls

- Passage

- Privacy

- Keyed

- Storeroom

- Classroom

- Trim around Panic Devices

In addition:

- Door type

- Door Thickness

- Door Schedule – so we can label specifically for quick job placement and installation.

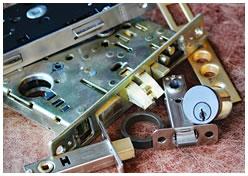

- Manufacturer of active mortise box, latches or exit devices.

- If Residential – do you require Multipoint trim or matching cabinet hardware?

Special Requirements

Depending upon the venue you are designing for, there may be certain code requirements for hardware application. While we typically design “trim” that goes on to others architectural hardware, we will raise any question you need to consider based on the job details you share with us. The requirement for pulls will be significantly different than active hardware, and residential specifications different than commercial applications.